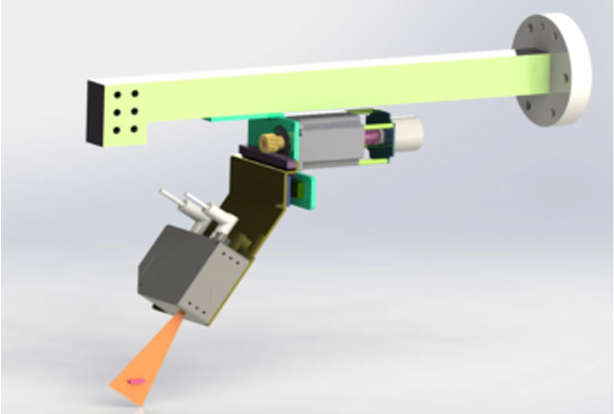

1. 7-axis of robot

2. RFID position/ QR codePosition

3. positioning by electric cylinder

4. carbody

5. AGV+roller bed

6. Robot

7. Control system

8. Robot control cabinet

9. Electrical control cabinet

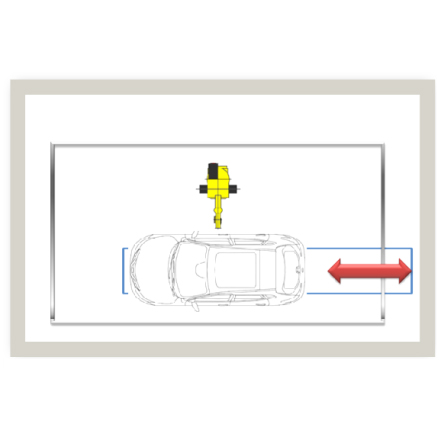

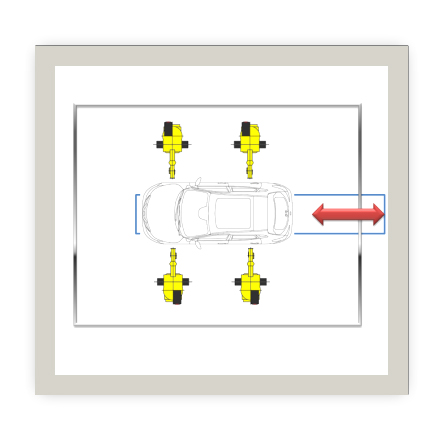

• As shown in the figure, the carbody is divided into four parts. Robots with measuring devices can physically cover this area.

• 3D carbody filesmust be provided. In order to calculate the reachability of each welding spot by computer simulation.

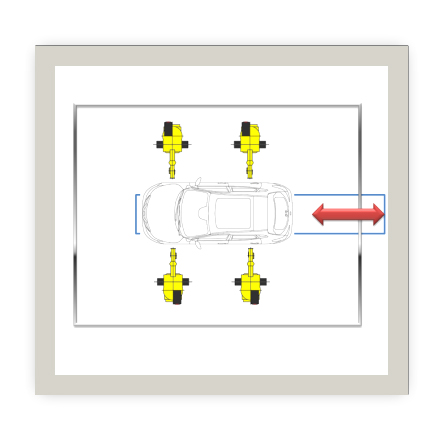

• Position and appearance detection

• Visual appearance inspection

• 4 Robot to complete 250 solder joint inspection takes only 5 minutes

• The cost of manpower and consumables is greatly saved

• The result of automatic solder joint inspection is more stable than that of manual inspection.

• It can realize the detection of the welding spot of the body

• Ultrasonic phased array equipment is adopted.

• Research and application of various visual means and core algorithms

• It has the function of timely feedback to the welding production of the body and the replacement of the electrode cap.

• Improve the quality traceability of spot welding.

* The coupling agent coupling can be replaced by water coupling in automatic detection